Client Success

Stories

We Do,

Stories Speak

Client success stories provide insights into how Kepner-Tregoe consulting and training services resulted in measurable improvements in targeted KPIs.

Client success stories are organized by industry, but many are relevant across industries because they illustrate dramatic results based on the application of analytic thinking to the problems, plans and decisions made by individuals and teams in our increasingly digitized and changing business environment.

A Systematic Approach to Investigations Yields Rapid Results

Challenge

In a continuous quest to achieve manufacturing excellence, site managers explored opportunities to reduce the number of investigations as well as the number of days required to close their investigations. The plant did not have a standard, systematic approach to finding the root cause of manufacturing deviations. In fact, engineers and scientists often relied on trial and error approaches that delayed investigations or created recurrences of deviations because true cause was not found and corrected. Site managers believed that by adopting a formal methodology to ensure faster time to closure on investigations, they would be able to reduce the number of investigations and improve investigation results.

Result

The work plan to improve the investigation process and incorporate KT as the investigation methodology was completely developed and implemented in less than six months. Within a year of identifying this opportunity for improvement, management and investigations teams reported a new confidence in their ability to conduct investigations quickly and accurately. Comparing year-to-year, investigations fell by 33% using the new approach. When compared with the previous year, closings dropped 13%. As a result of these successes, investigation teams are more focused and disciplined, and systematic KT approaches have been integrated into other business functions to facilitate concerns and critical decision making.

A Systematic Approach Targets Next-Generation Drugs

Challenge

When a leader in the discovery, development, and commercialization of new medicines wanted to improve the success of product development, Kepner-Tregoe (KT) helped focus their efforts. The company leadership wanted to act more strategically, optimize processes for the identification of new ideas, and refine the way new product projects were selected—without stifling creativity or limiting new ideas brought forward for review.

Result

The chance of success of the carefully chosen projects is enhanced because: The multiple, weighted objectives that guide project selection address key strategic indicators of success including the target product profile, commercialization, probability of successful product discovery and development, and strategic alignment. Cost, time, and quality standards are factored in by including them in the weighted objectives. The sponsors and teams working on the projects that are not selected for development understand and support the choices made. The clarity of the decision process helps them “let go” of projects that are not chosen.

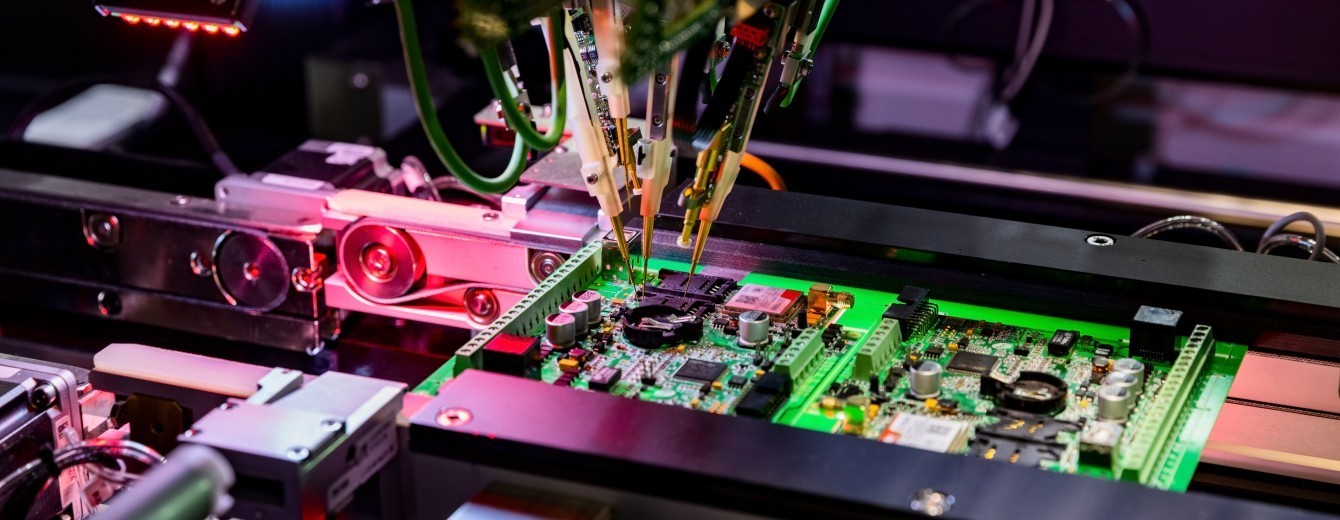

When Advanced Technology Presents Problems Never Seen Before, KT Problem Analysis Prevails

Challenge

As part of a joint development agreement with a European R&D center, TEL engineers are developing a new high-k semiconductor process based around the company’s TELFORMULA vertical mini-batch furnace using 12-inch silicon wafers. The experimental process was tested in Japan and transferred to the customer site’s machine—one of a handful of similar tools worldwide. After initial success, the product from the customer tool began to exhibit poor thickness repeatability. This was blamed on tool-to-tool variances and addressed by tuning the process. When this did not fully resolve the problem, a specialist was flown from Japan to assist in finding the cause. While he was able to address some minor issues, the thickness problem remained unresolved. Eighteen months after installation, the tool was still unreliable.

Result

Using KT rational process, an 18-month old problem was resolved in two months, full confidence in the state-of-the-art tool was restored, and the relationship between TEL and the client was strengthened. Today this Problem Analysis is used in engineer education and it is credited with opening new lines of global communication. During this same period at the R&D lab, ongoing problems with a competitor’s tool were never resolved and the tool was abandoned by the competitor. When the customer’s new technology is eventually adopted, TEL is poised to provide more new tools—each with a multi-million dollar price tag.

Rio Tinto’s Kennecott Utah Copper Copperton Concentrator Plant

Challenge

Each year the concentrator plant at Kennecott Utah Copper is shutdown a total of 36 times. This is necessary to maintain critical equipment—as essential repairs and upgrades are completed. The issue at the Bingham plant was that the length of downtime was causing a bottleneck in the overall process. As the production process is suspended, so is the sale of copper and other associated materials representing millions of dollars in lost revenue. KUCC has a strong corporate culture that produces many highly-skilled and experienced staff passionate about their work. Even with remarkable dedication and hard work, the shutdown process continued to show variations in the stated time, cost, and scope. With a commitment to improve this result, KUCC invited Kepner-Tregoe (KT) to assess the situation and work with their team to eliminate the bottleneck.

Result

The collaboration and implementation paid off. The shutdown process saved over $11 million in the first year of implementation. On-time performance improved by 60% and is tracking towards world-class results. key performance Indicators (KPls) for shutdown performance improved over all prior years. Team performance (on-scope, on-cost) improved by 60%. Shutdown administrative work load fell by over 50% allowing team members to focus on other areas such as reducing cost or generating more revenue. All Injury Frequency Rate (AIFR) improved, advancing a strong safety culture which is a core value of KUCC. The concentrator plant improved to the point where it is no longer the bottleneck in the process. Team confidence has increased as stress has been reduced. There is a renewed sense of confidence at KUCC as they now manage their business proactively.

Problem Analysis Improves Productivity

Challenge

Build-up in the reactor tanks requires inspection and cleaning after a set number of batches. Cleaning was done after every three or four batches until the 1970s when suppressants were developed that reduced build-up to levels that required cleaning after 30 batches. In the 1990s, a new mix and application should have allowed the plant to extend maintenance to 200 batches between inspections and thousands of batches between cleanings. However the Laverton reactors still needed more frequent cleaning, which added time and cost to production.

Result

The initial objective was to extend the life between cleanings to 250 batches. When the project was declared complete, one reactor was at 450 batches and still going strong and the other had achieved a successful 250-batch inspection after the last set of changes had been made. The increase in productive time added 3,000 tons of PVC resin production and significantly improved profit. However the biggest effect was that the initial project acted as an enabler for additional productivity improvements. Ultimately, improvements increased annualized production by over 20,000 tons, with a significant increase in profit.

Why KT?

Run More Efficiently

KT will help you to clarify and remove recurring and

high-impact issues, supporting smoother and more

cost-efficient business operation.

Confidence Under Pressure

KT's unique critical thinking methods are designed to

support you in situations of maximum stress. When it

really matters that you find the best solution, the KT

toolkit is proven to deliver.

Process Plus Experience

KT consultants have a wealth of experience in

supporting clients use of the KT methods in a wide

variety of industries and situations. We can help you

get the maximum value from deploying the KT

toolkit.

Our Experts Are Always Ready to Help

- North America

- Europe

- Asia

- Japan

We are experts in:

Contact Us

For inquiries, details, or a proposal!